|

HOME • ABOUT CONNEX • SPRING BUSHINGS • SPRING PINS • REQUEST INFORMATION |

|

|

|

E-MAIL: info@connexusa.com Voice: 814-474-4550 Fax: 814-474-4577 CONNEX Inc. |

|

|

|

|

|

|

|

|

Spring Pin PropertiesPin MaterialCONNEX Spring Pins are manufactured in the following materials: AISI 6150 Chrome Vanadium Spring Steel accouding to DIN 1.8159 |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Pin HardnessCONNEX Spring Pins of material AISI 6150, DIN 1.8159 are hardened to 42 to 50 HRC. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hardness Comparison Table: |

|||

|

Rockwell HRc |

Rockwell Hra |

Vickers HV |

Tensile Strength PSI* |

|

42 |

71.5 |

412 |

194,000 |

|

43 |

72.0 |

423 |

201,000 |

|

44 |

72.5 |

434 |

208,000 |

|

45 |

73.1 |

446 |

215,000 |

|

46 |

73.6 |

458 |

221,000 |

|

47 |

74.1 |

471 |

229,000 |

|

48 |

74.7 |

484 |

238,000 |

|

49 |

75.2 |

498 |

246,000 |

|

50 |

75.9 |

513 |

255,000 |

|

51 |

76.3 |

528 |

264,000 |

|

52 |

76.8 |

544 |

273,000 |

|

53 |

77.4 |

560 |

283,000 |

|

54 |

78.0 |

577 |

292,000 |

|

55 |

78.5 |

595 |

301,000 |

|

56 |

79.0 |

613 |

313,000 |

|

57 |

79.6 |

633 |

325,000 |

|

58 |

80.1 |

653 |

338,000 |

|

59 |

80.7 |

674 |

351,000 |

|

60 |

81.2 |

697 |

364,000 |

|

*Inexact and only for steel |

|||

|

|

|

|||||||

|

|

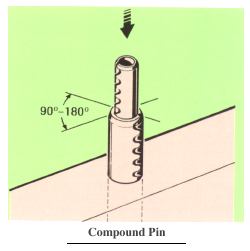

Compound PinIf a higher shear strength is required from a connection than originally estimated, a combination of two pins can be used. The shear strength can thus be invreased by 35-40%. CONNEX Spring Pins, type S, should be used. the postion of the slots should be at an angle of between 90º-180º to each other. Surface ProtectionConnex Spring Pins made of material AISI 6150 are supplied with a lightly oiled black surface. Ground CONNEX Spring Pins are lightly oiled with a bright surface. CONNEX Spring Pins made of AISI 301 stainless steel have an untreated surface. Special Surface ProtectionSpecial surface protection demands can be met through phosphatising, zinc flake coating or electroplating. A possible reduction in shear strength as well as the danger of hydrogen embrittlement must ge taken into consideration. A customer doing their own surface protection should be cautious of this factor. |

|

|

|

|

|||

|

|

|

|

|

|||||

|

|

Spring Pins - Standard and Ground Shear Resistance and Material Strength Heavy Spring Pins (Inch Sizes), Type S Ground Heavy Spring Pins (Inch Sizes), Type SG Heavy Spring Pins (Metric Sizes), Type S |

|

|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

ABOUT CONNEX • SPRING BUSHINGS • SPRING PINS • REQUEST INFORMATION |

|

|

|

E-MAIL: info@connexusa.com Voice: 814-474-4550 Fax: 814-474-4577 CONNEX Inc. 7660 Klier Drive N., Fairview, PA 16415 |

|

|

|

|

|

|